5 winter checks: tips from our technician

For performance and safety in the winter months experienced AGCO Technician Ashley Briggs recommends you do these machine checks now.

1. Battery Health Check

It may sound so simple that it’s easy to overlook, but when you consider that almost everything on our machines runs on electricity these days, the battery health is the key component. If that isn’t right, then you can’t expect anything else to be right either.

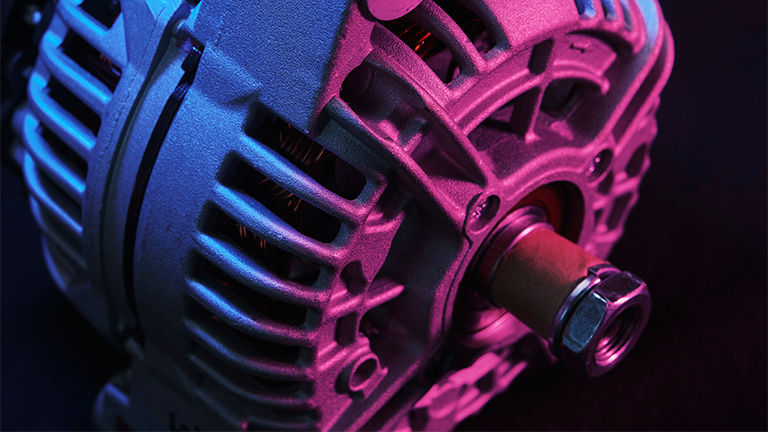

2. Alternators

Checked its output voltage and charging amperage. An operator or technician can quickly check the output voltage with a Digital Multimeter whilst the engine is running. On a 12V system, a good, expected charging voltage is usually around 14V (typically 14.4V). The voltage is only half the story, as it is the amperage (amps or current) that actually makes things work. To test the charging amps of an alternator, an 'amp clamp' must be used. This will measure the charging amps inductively, detecting the strength of the magnetic field of the current created in the alternator and calculating how many amps have created it. It’s a bit scientific!

3. Tyre Pressure Checks

As the tyre is the one component that is in contact with the ground on any vehicle, its condition is very safety critical. There are several, mostly observational checks that can be carried out by an operator – and this is true of any vehicle, not just agricultural.

4. Cooling System Checks

While the cooling system is designed to cool the engine down, it relies on a mixture of antifreeze and distilled water, mixed at a 50:50 ratio. Too much water in the anti-freeze (or none at all in some cases) can and will freeze, as we know water expands when it freezes - this has been known to damage pipes or radiators and even crack engine blocks.

5. Components of your steering system

For steering, the most obvious check would be for all the rubber boots on the steering ball joints. These rubber boots work to keep the lubricating grease in the joint but also keep water and debris out. Over time, the rubber degrades and/or gets damaged by the rigours of work. Naturally, water making its way into the ball joint will cause corrosion and eventually lead to the joint's failure. A visible check of rubber boots is usually all that is required, with a view to replacing ball joints if the boots are split or damaged.

Looking for parts for your AGCO machine?

For quality parts that last ask your dealer for AGCO Parts for your Fendt, Massey Ferguson or Valtra machine. Or shop at AGCO Parts online 24/7.

Ashley Briggs

Ashley Briggs has over 20 years of expertise in the automotive sector, having spent 15 years as a technician and auto-electrician before transitioning into technical training. He now leads the AGCO Apprenticeship Scheme for the UK & Ireland, where he’s spent the past 18 months dedicated to helping shape the next generation of agricultural engineers